Step 3_ MINERS AND MINES: THE DEVOURED MOUNTAIN*

Route to Gallarta: 6 km

Route to Gallarta: 6 km

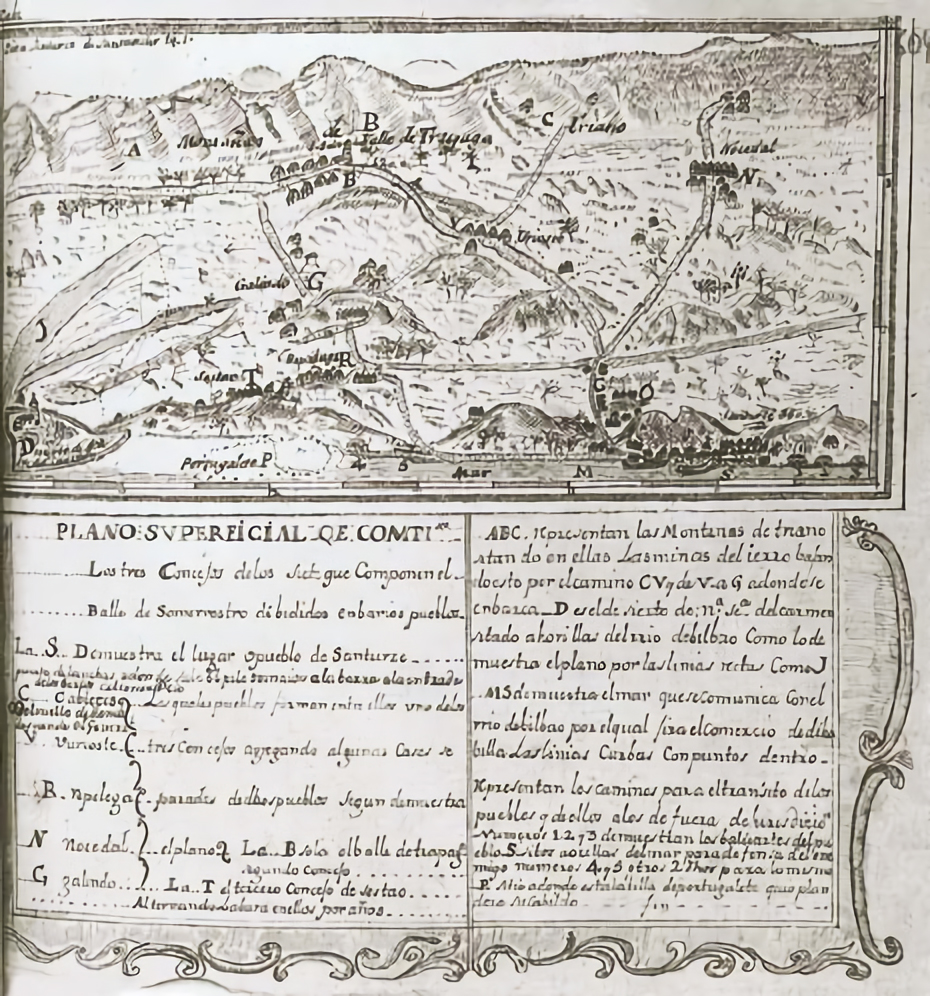

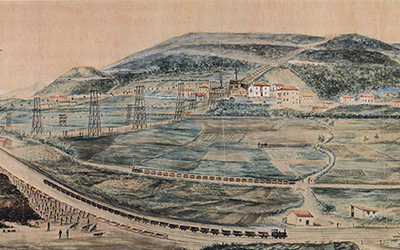

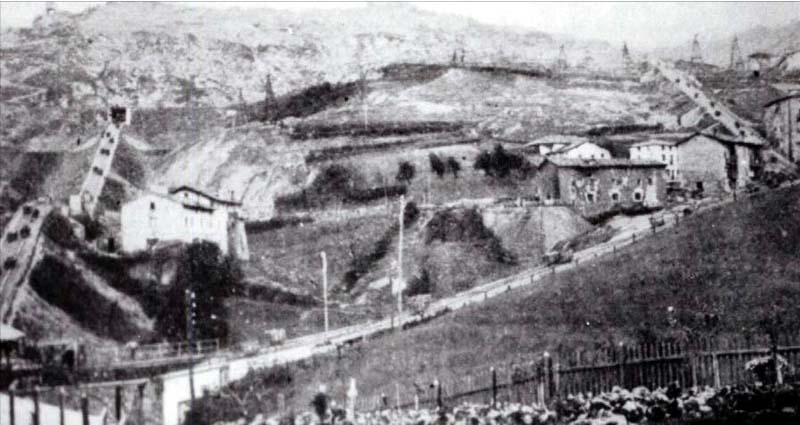

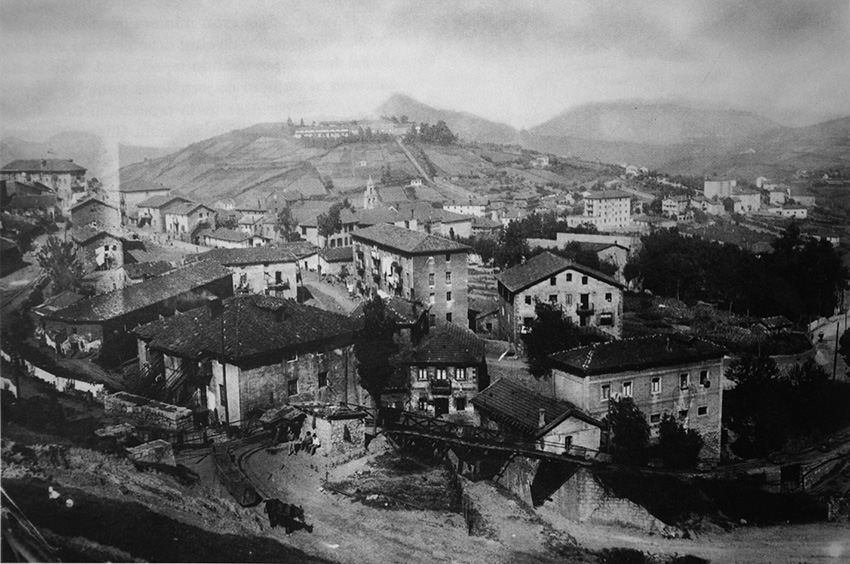

Until the great mining era, the inhabitants of the valley of Somorrostro and Barakaldo combined agricultural work with extracting and hauling ore to the ports.

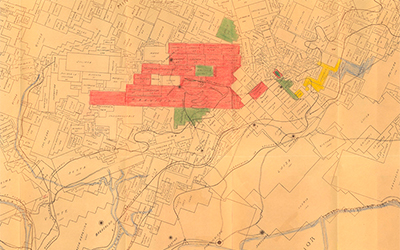

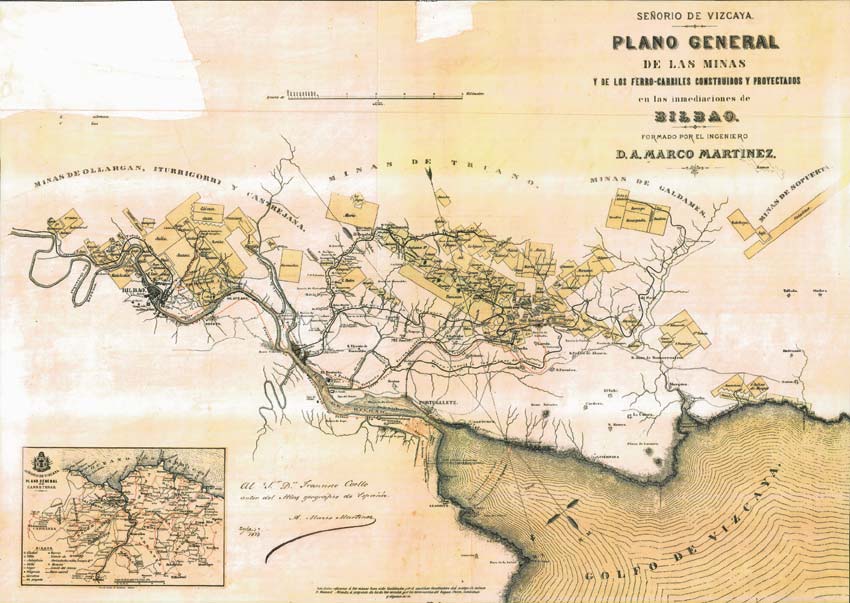

Ownership of the Triano mountains until the late nineteenth century was in the hands of the seven councils of the Valley of Somorrostro, which distributed it for communal use (such as forests for wood used in foundries, homes, shipbuilding and construction).

The use of the mountains was unregulated, work was simply prohibited outside the summer months and the number of animals for haulage was limited.

Until the nineteenth century, iron ore could be taken from the mountains without title deeds or any specific limitation. In order to extract the ore it was enough to place a cross made of stones on the ground, to show that the site was in operation. This was because the size of the seams was proportionate to the lack of consumption, and the metal had no appreciable value. Ore was mined as if one were chopping wood.

The mining laws of 1859 and 1868 allowed greater extension of mines and suppressed limits of ownership. Mines were demarcated, even when they were not mined, around the most important areas and the largest tracts of land ended up in the hands of the big companies.

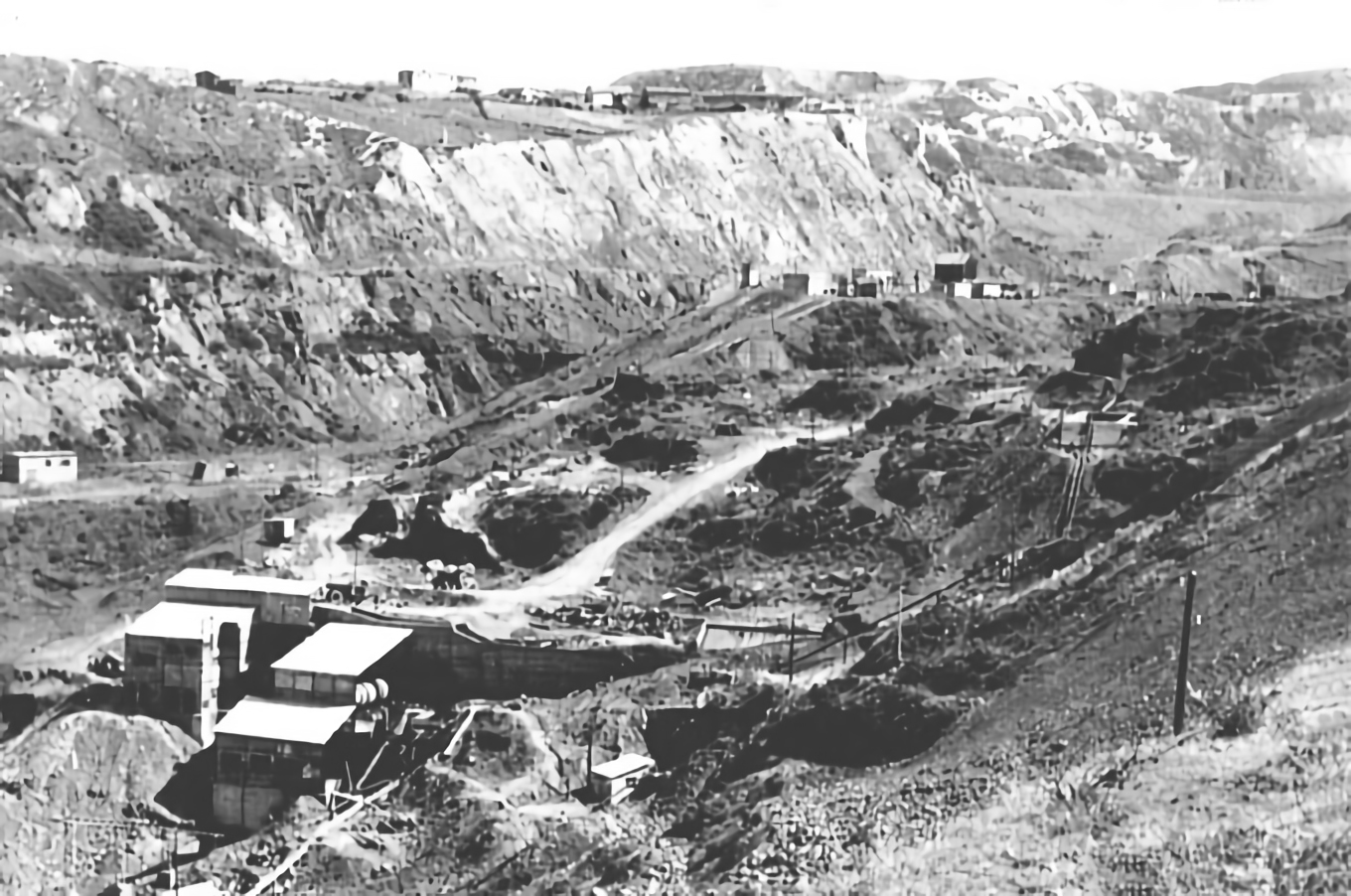

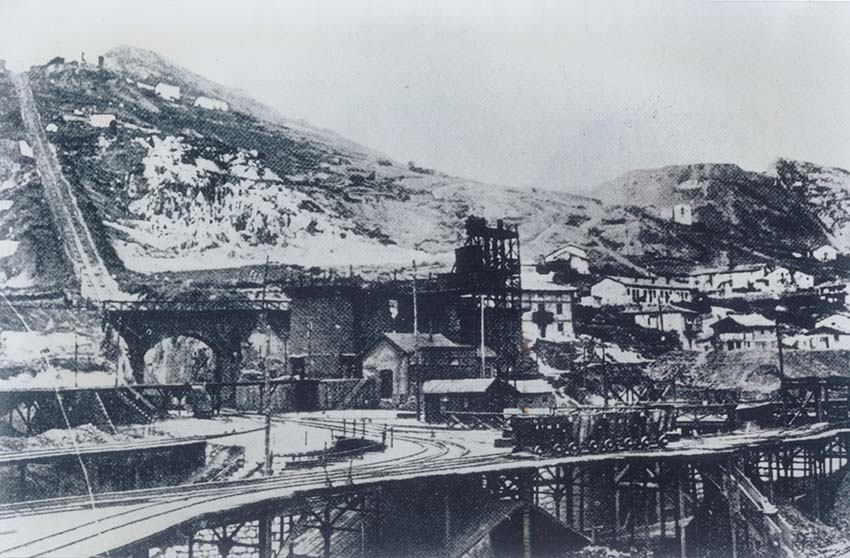

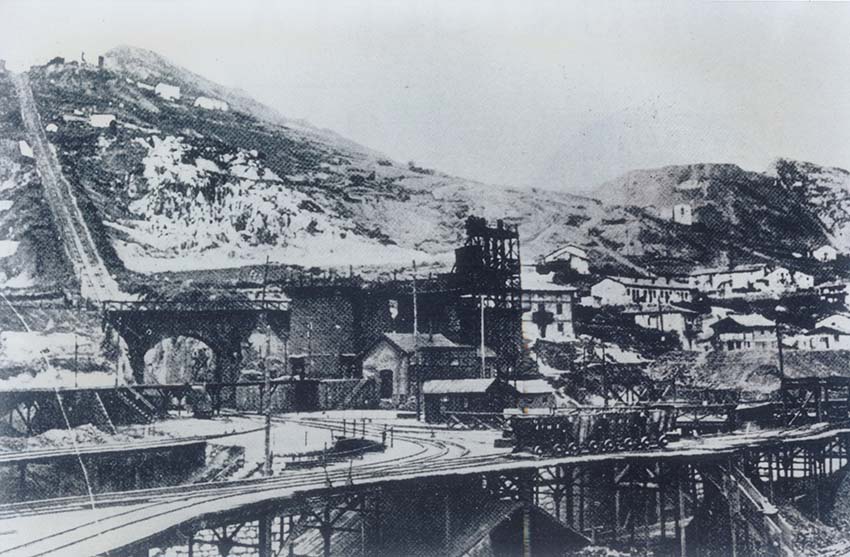

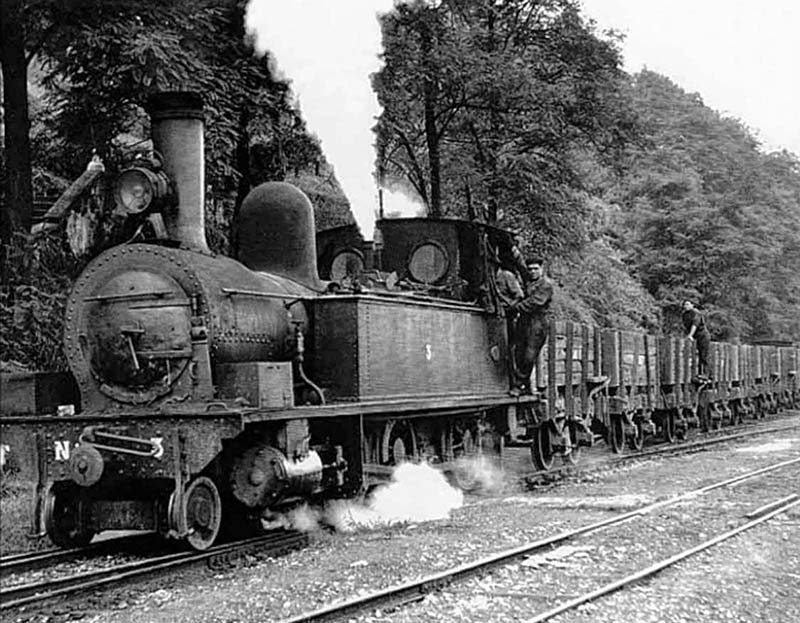

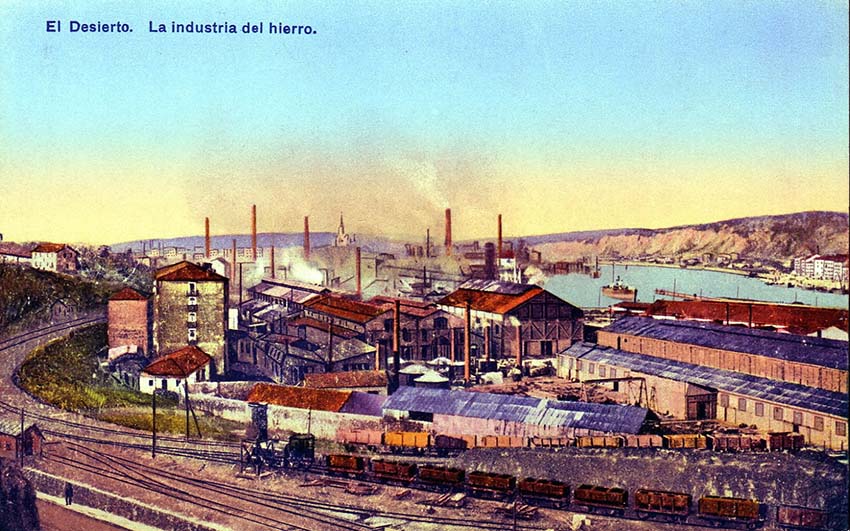

At the end of the Third Carlist War, in 1874, the real explosion in mining in the region occurred. The iron mines of Bizkaia and Cantabria brought in the latest technology and the best technicians and engineers of the time, with technologically pioneering infrastructure.

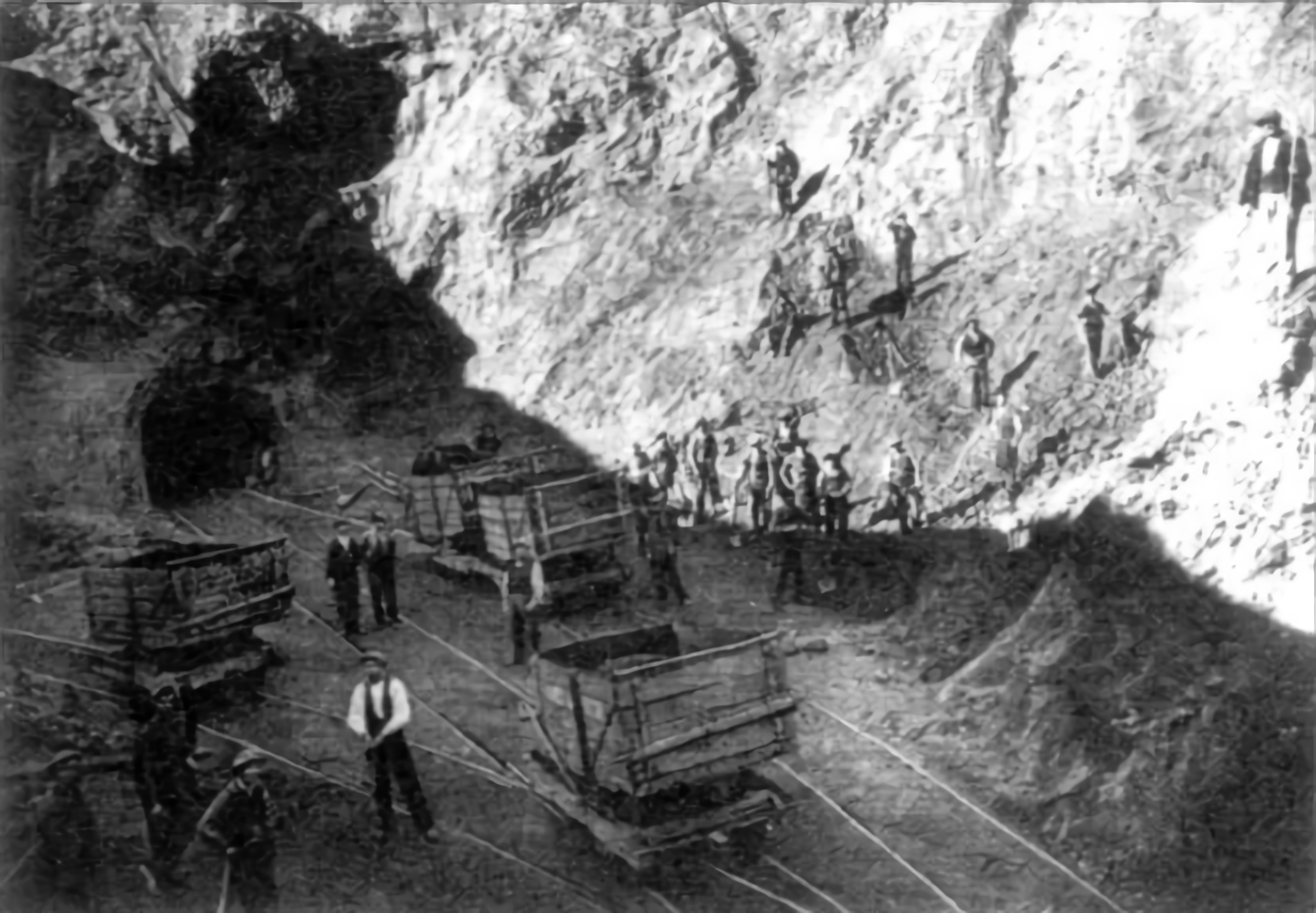

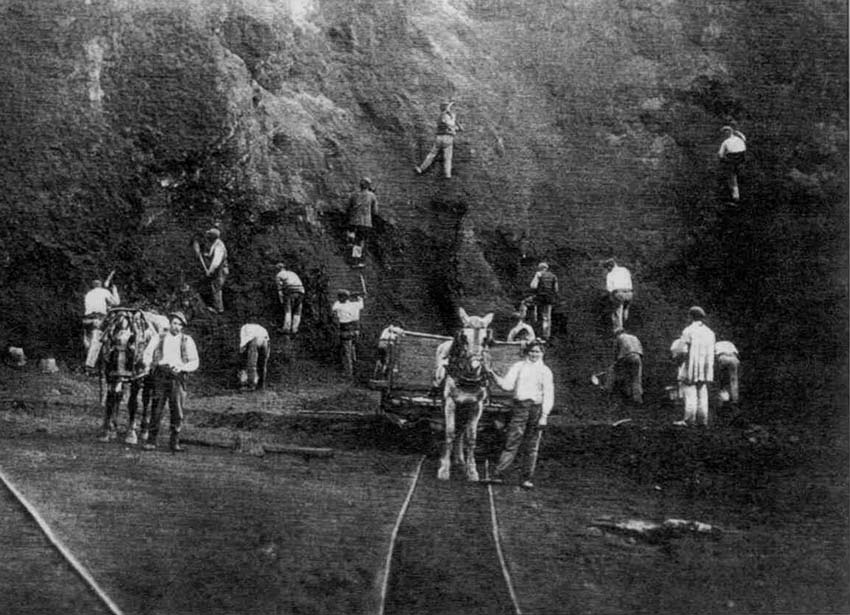

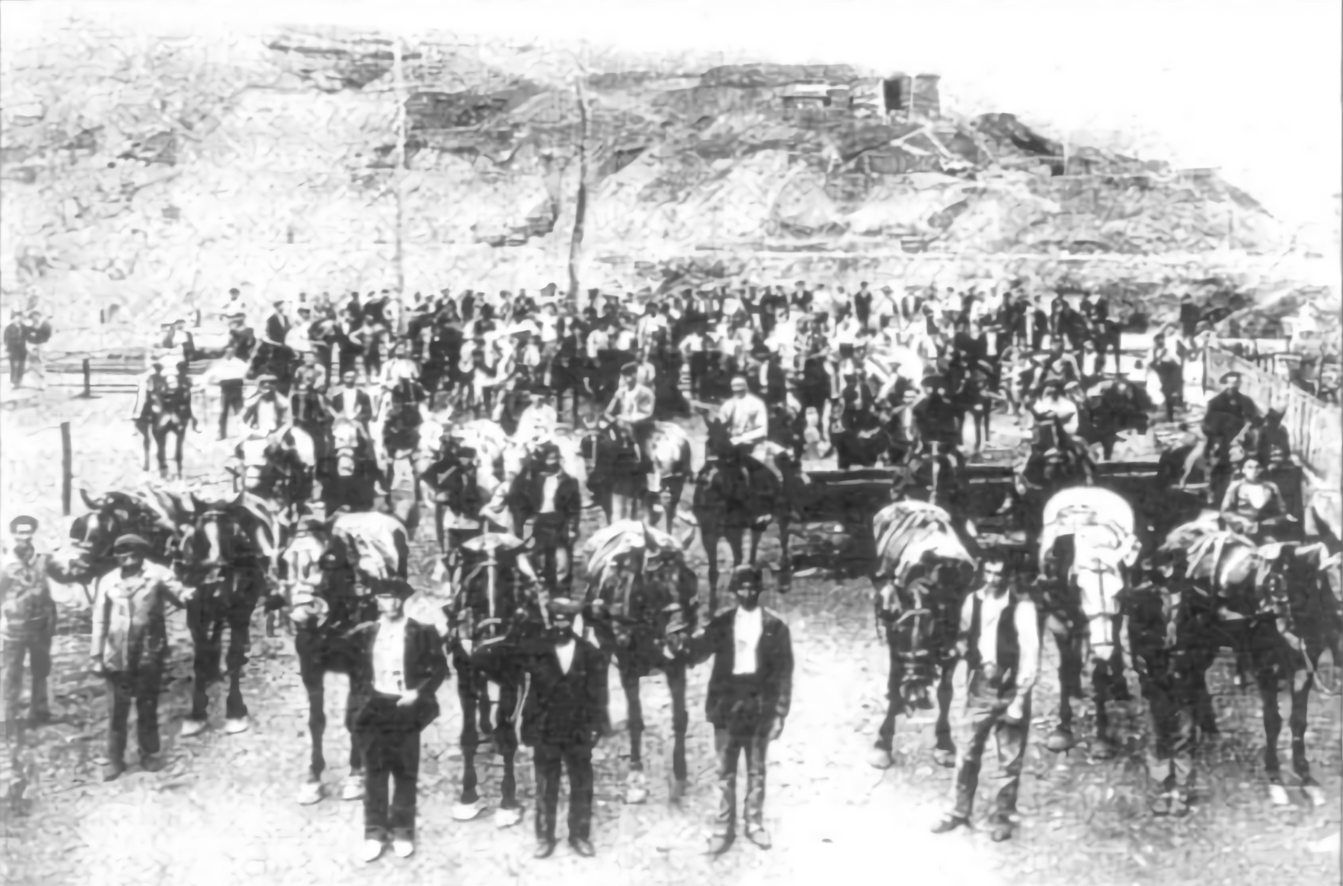

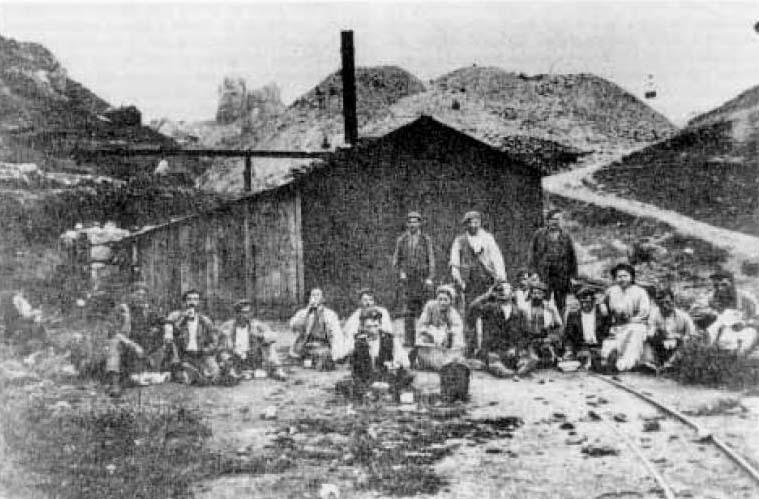

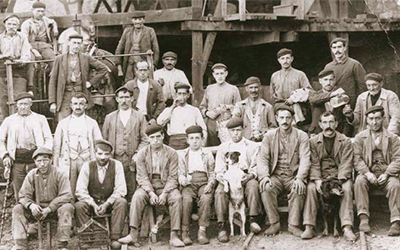

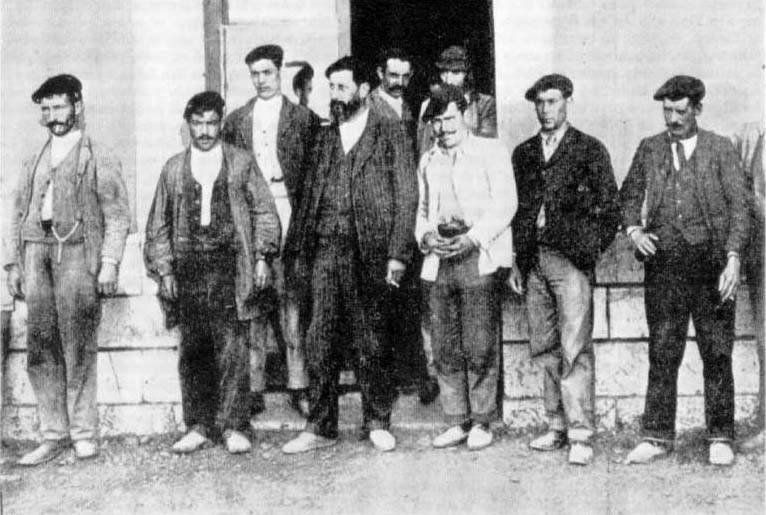

The mine was a new, unknown world, with new concepts and new jobs appearing: borers, ponymen, labourers, foremen, scalesmen, mine boys, company stores, guitars, bowling, country dances, mining accidents and strikes. The workday was not established in duration by any regulation. At the beginning, there were mines where people worked longer than from sunrise to sunset at the time of year with shorter days, and were only paid per day worked.

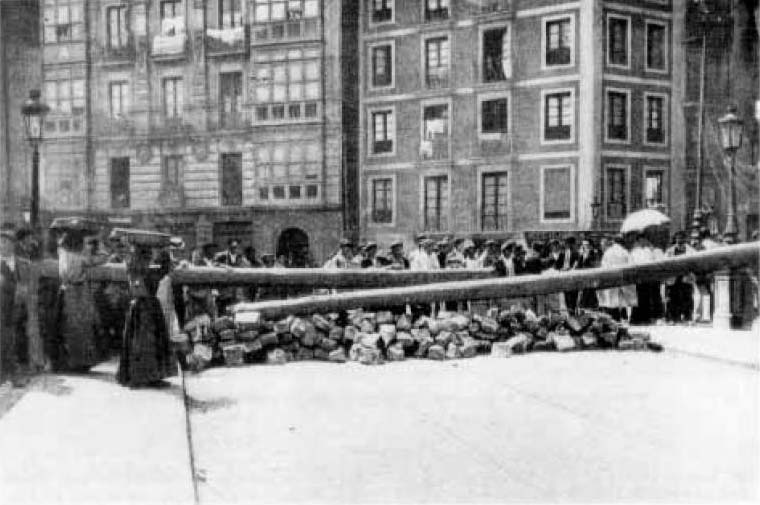

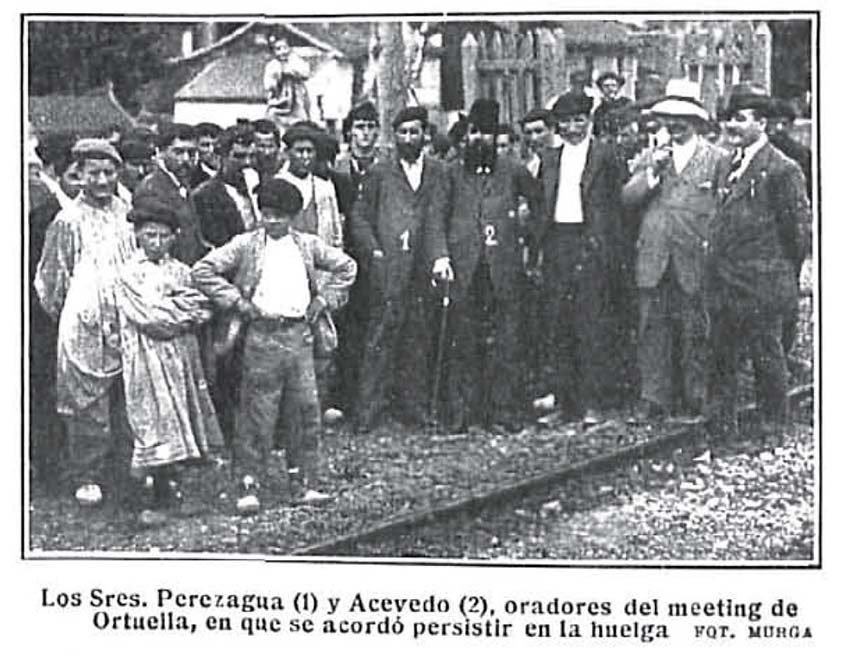

The harsh conditions around the mines (the rise in cost of living, the compulsory purchase of commodities in company stores operated by the foremen, hours and safety conditions) meant that life expectancy for those born in this area did not exceed 20 in the late nineteenth century. This situation led to 30 partial strikes and 5 general strikes between 1890 and 1910. Among the achievements of this succession of revolts, the most important were the elimination of the system of canteens and the reduction of hours to 9.5 hours (the workday was not reduced to 8 hours until 1919).

Life expectancy for those born in this area did not exceed 20 in the late nineteenth century

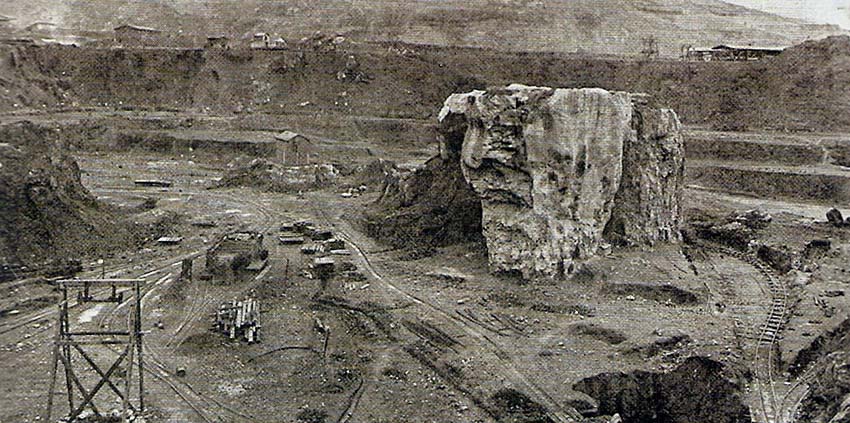

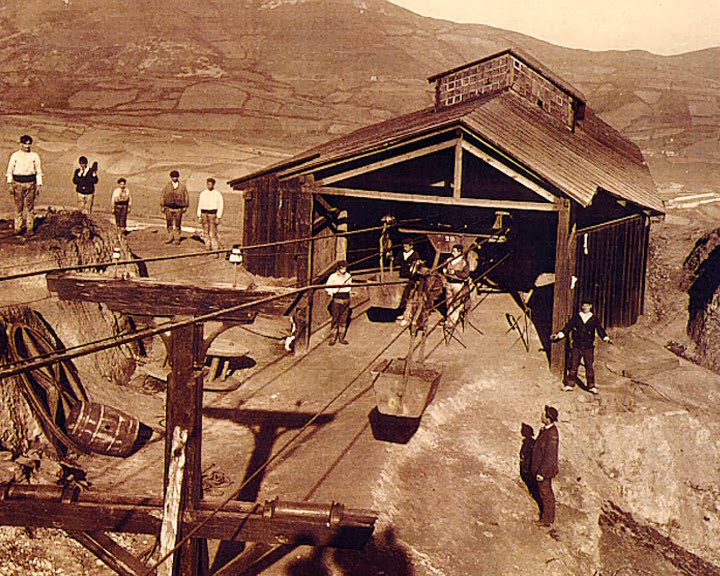

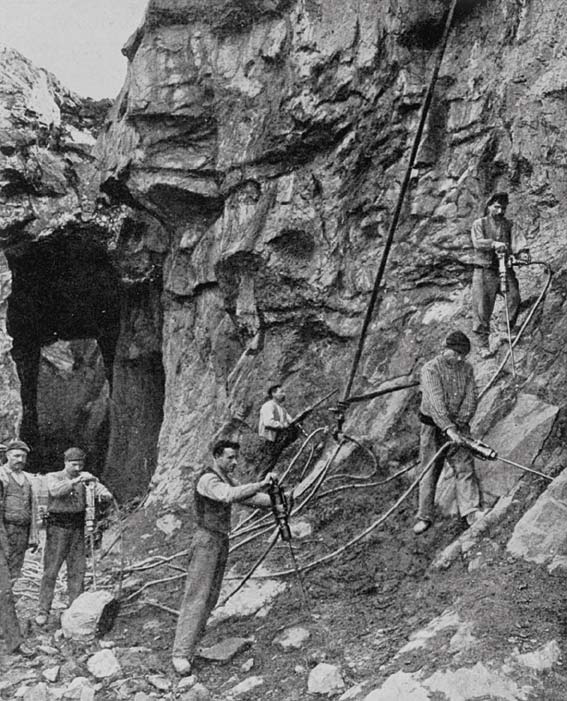

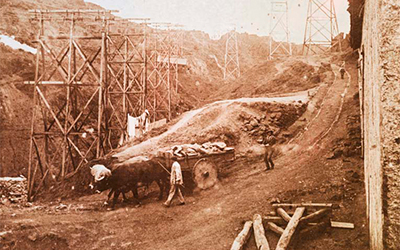

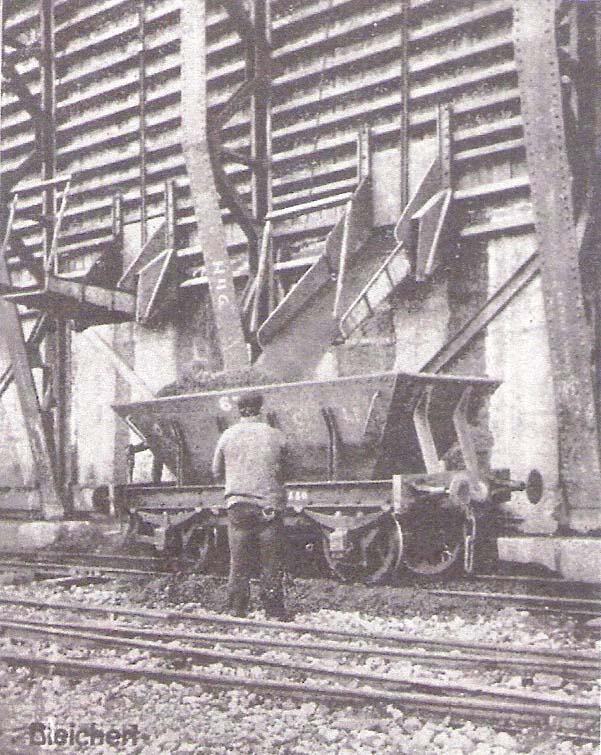

The iron ore was found on the surface of the soil. The mining system was similar to that of a quarry, using explosives to separate great blocks of ore. After blasting, the ore was broken up with picks and hoes, removing the debris with rakes and baskets.

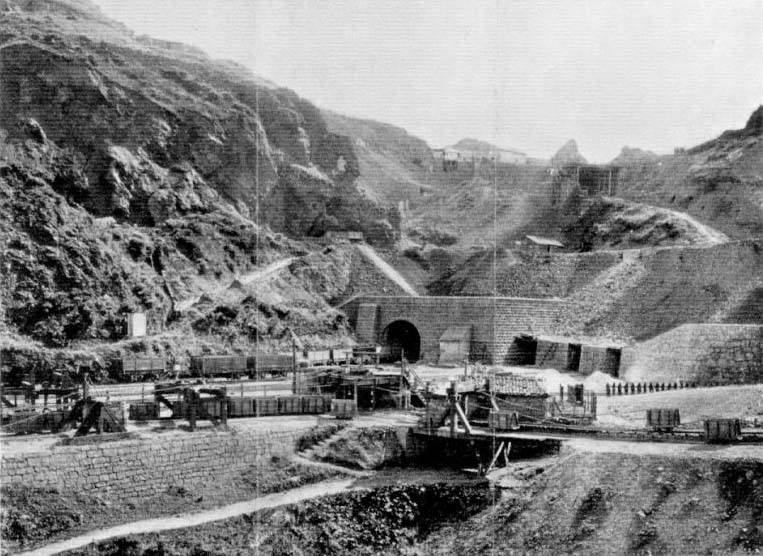

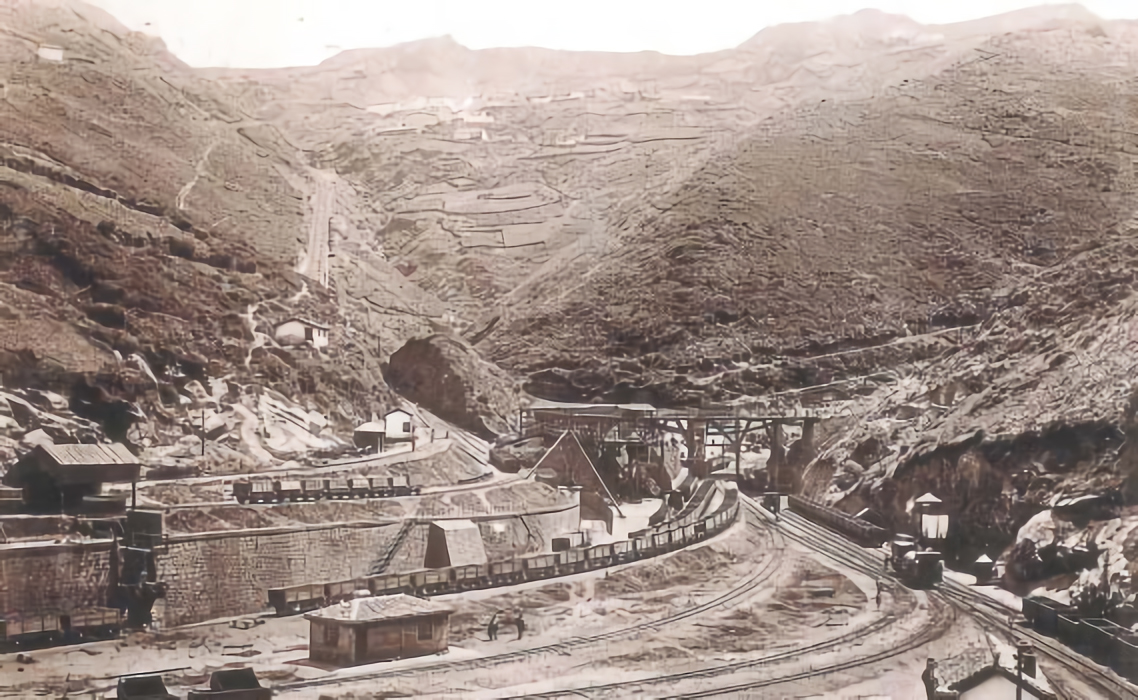

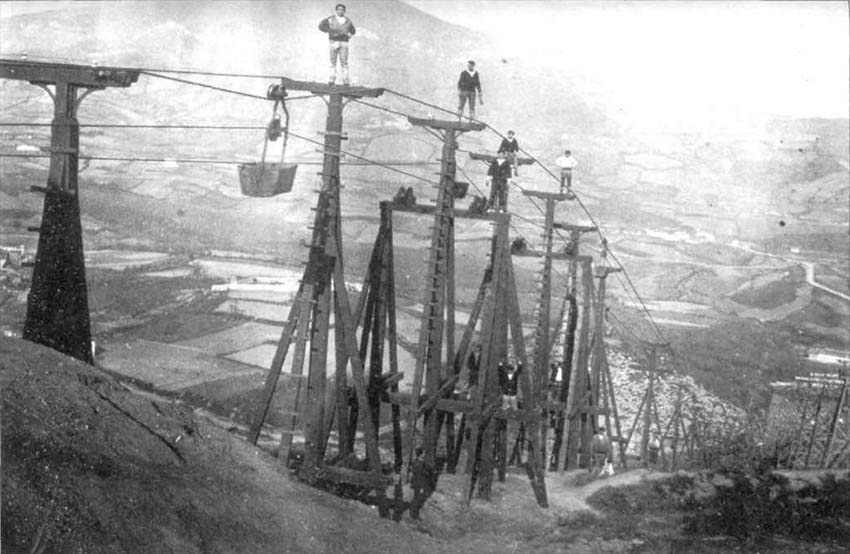

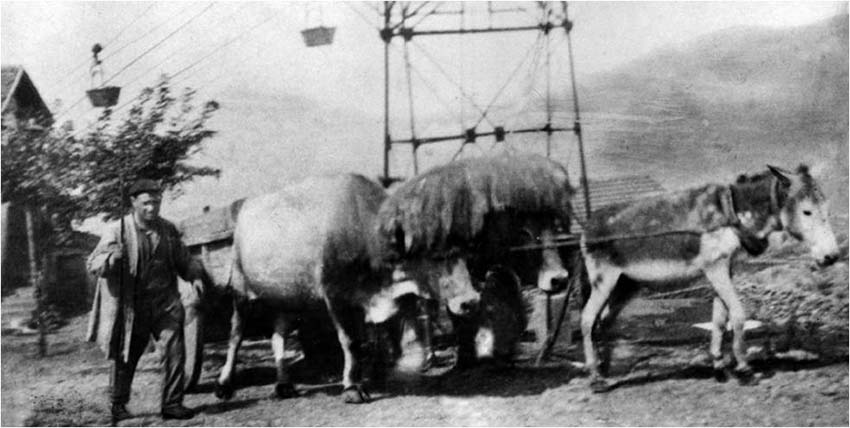

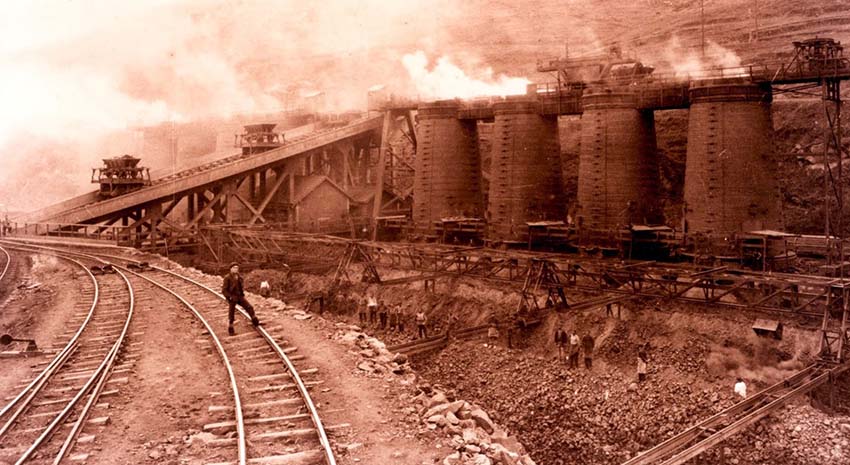

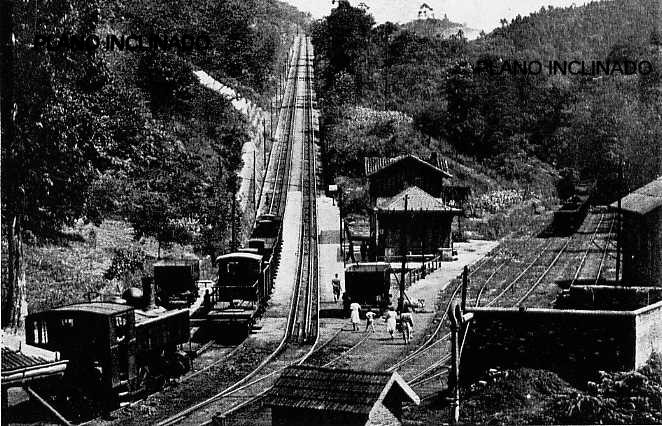

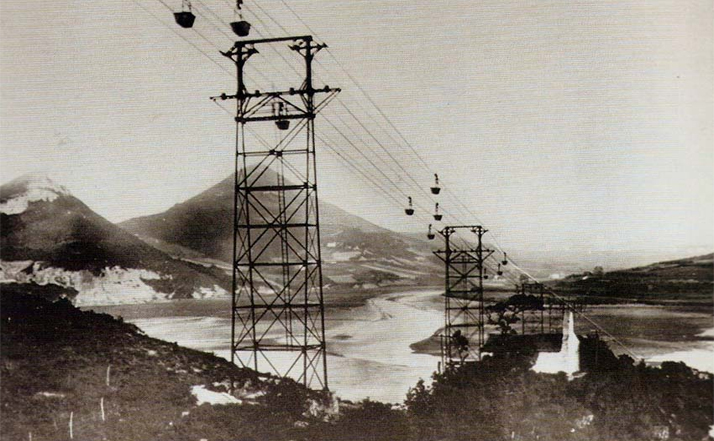

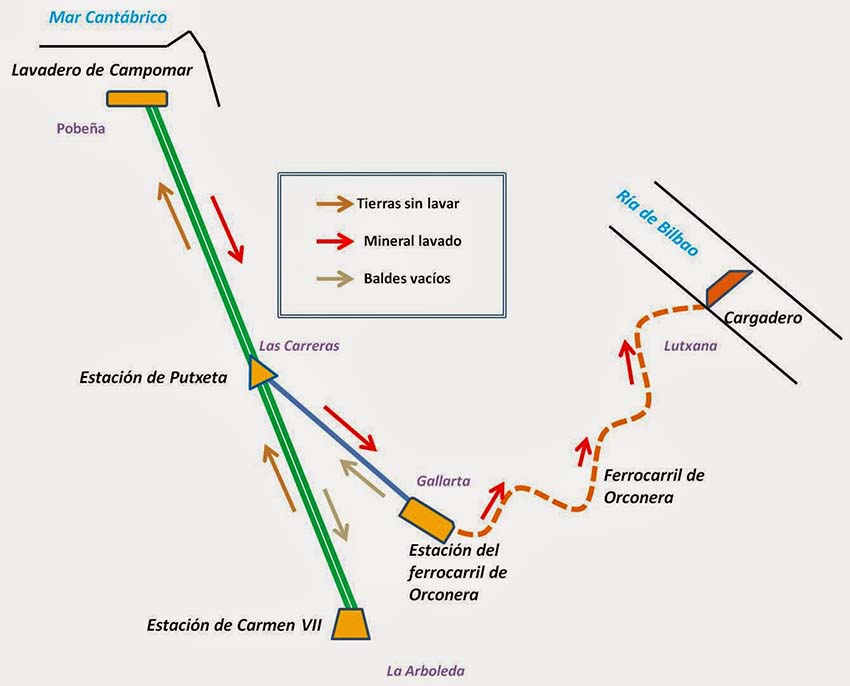

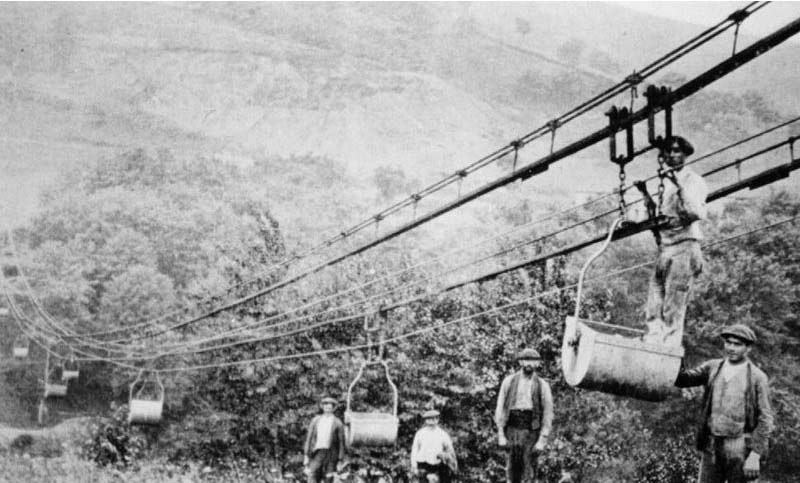

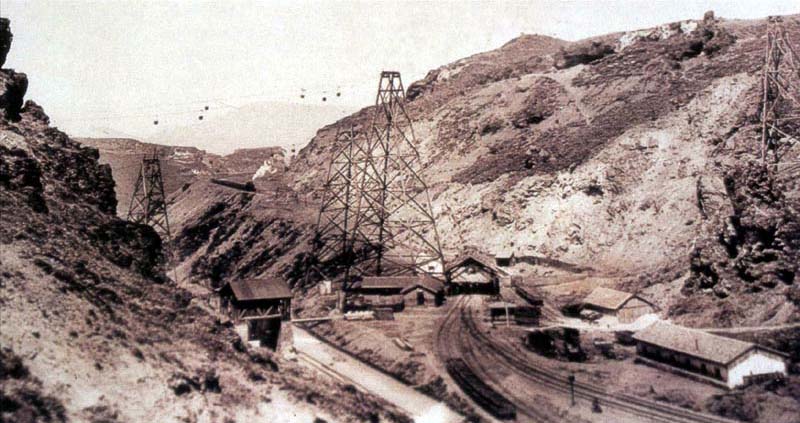

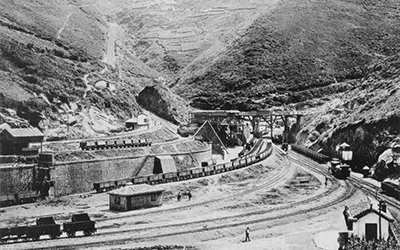

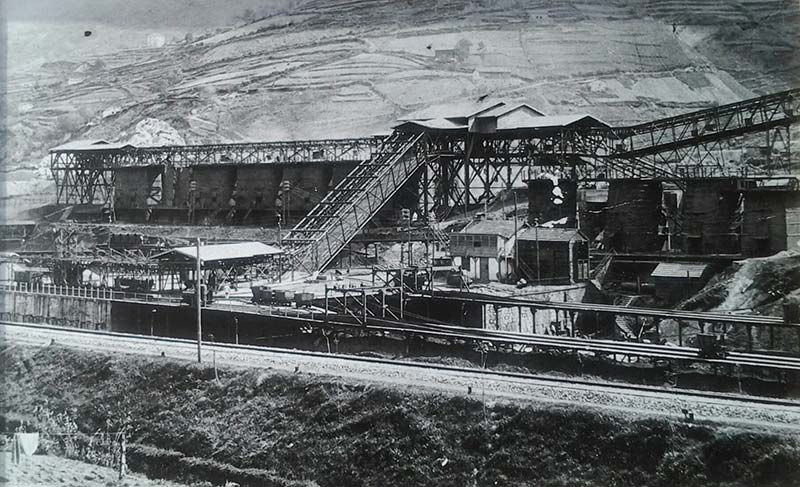

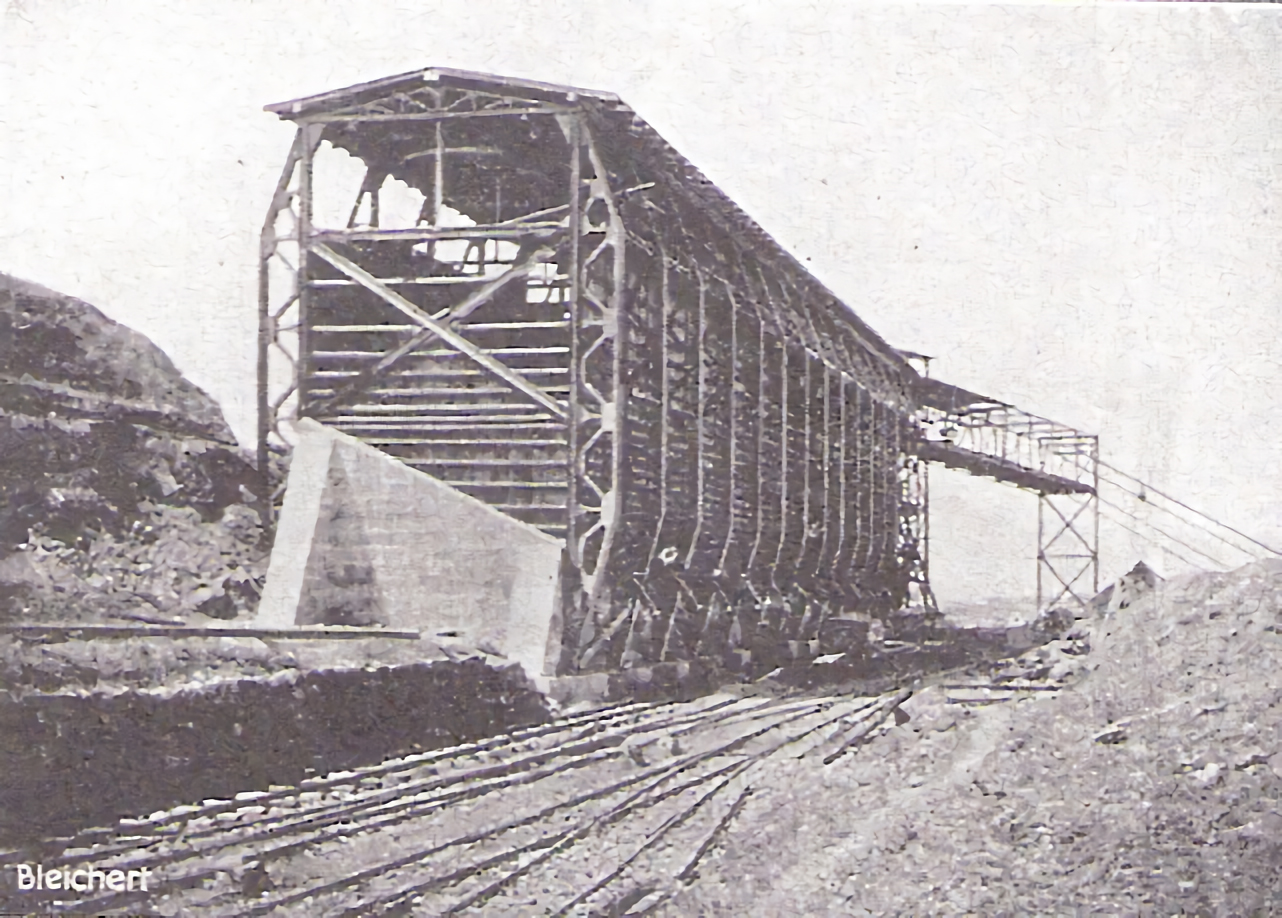

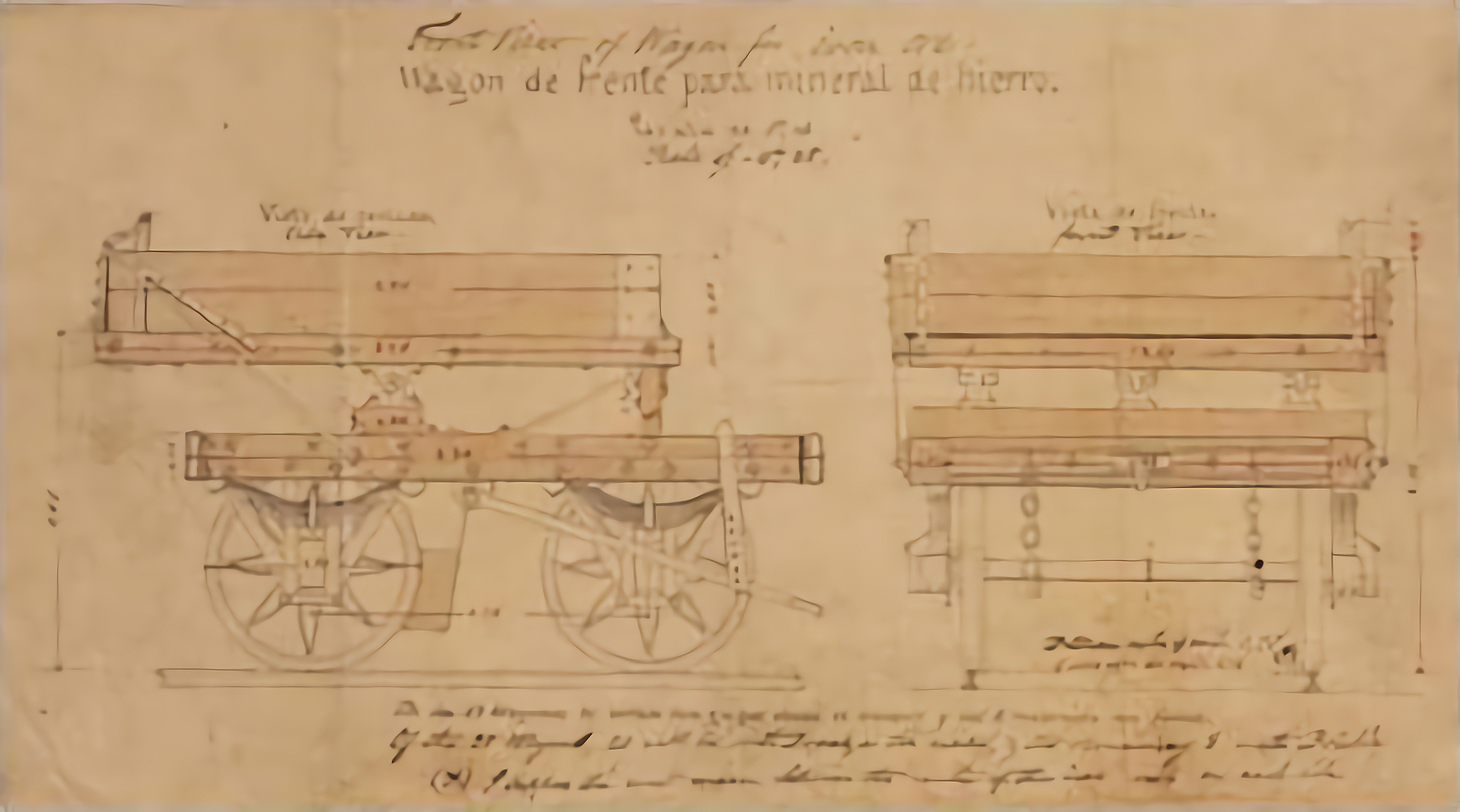

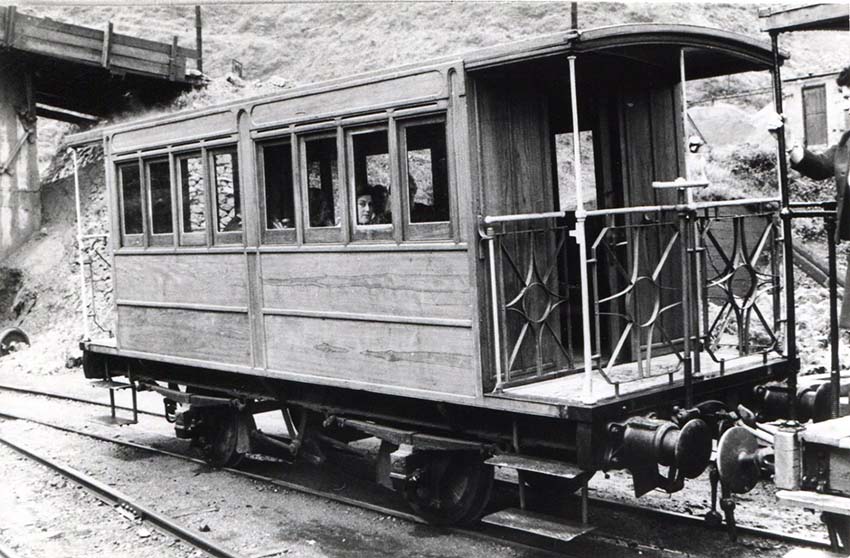

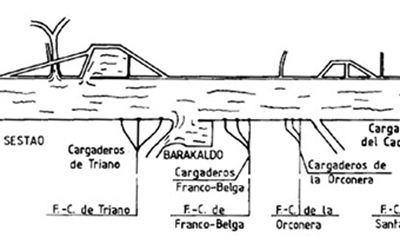

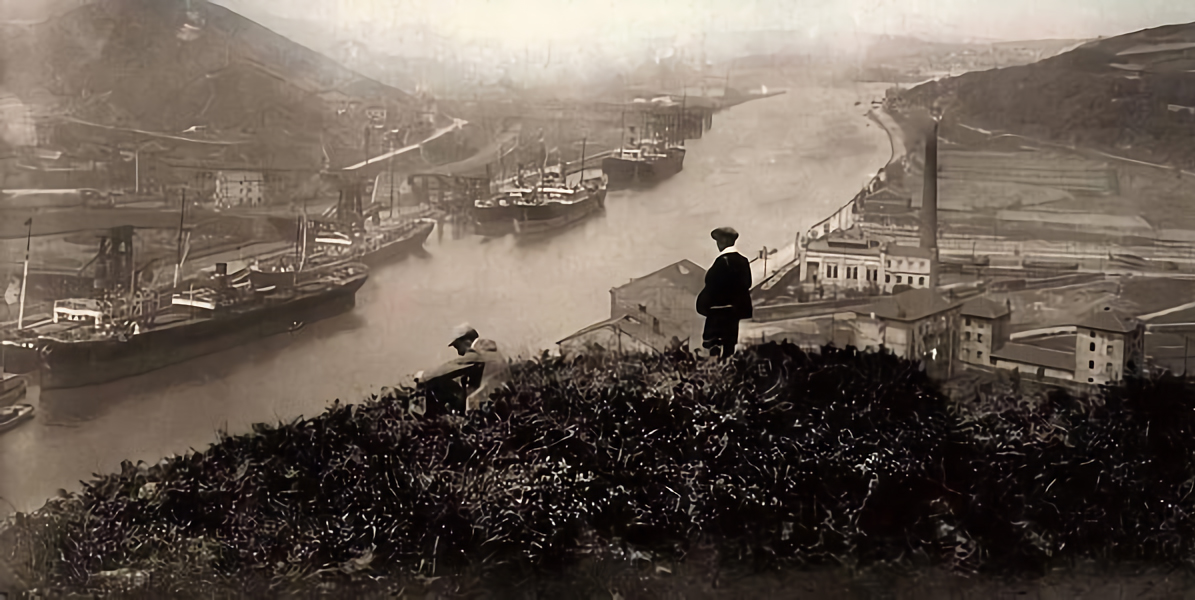

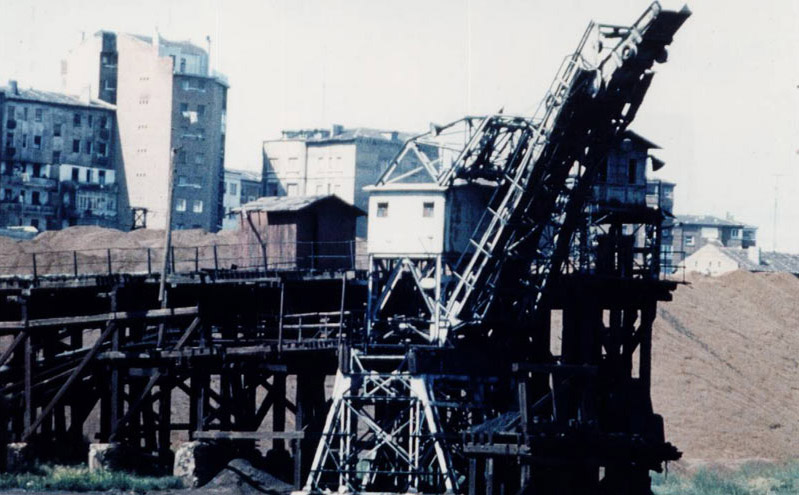

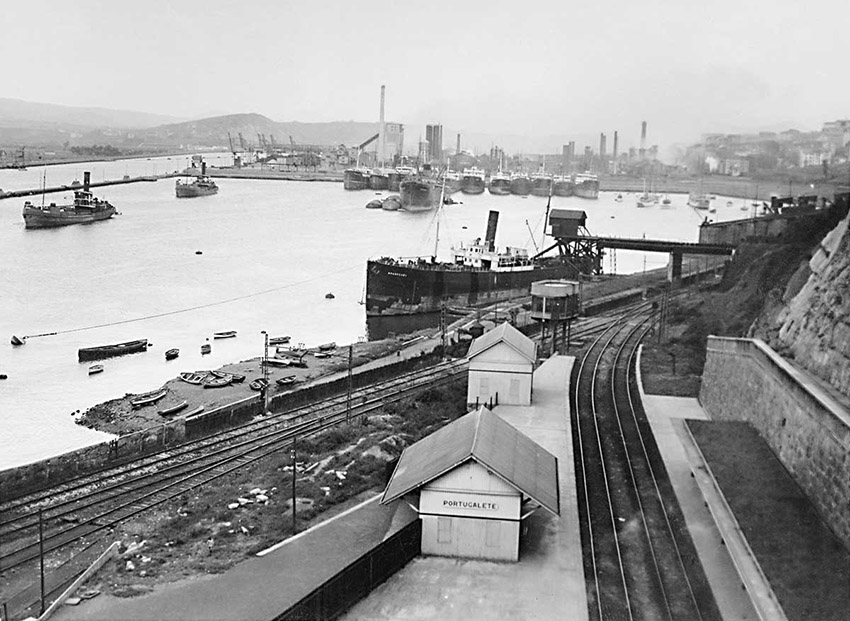

They started by loading the material onto mules, which were then replaced by inclined plane cable railways (from 1867), aerial tramways (1872) and railways (1865), which would take the ore to the 23 loaders along the river.

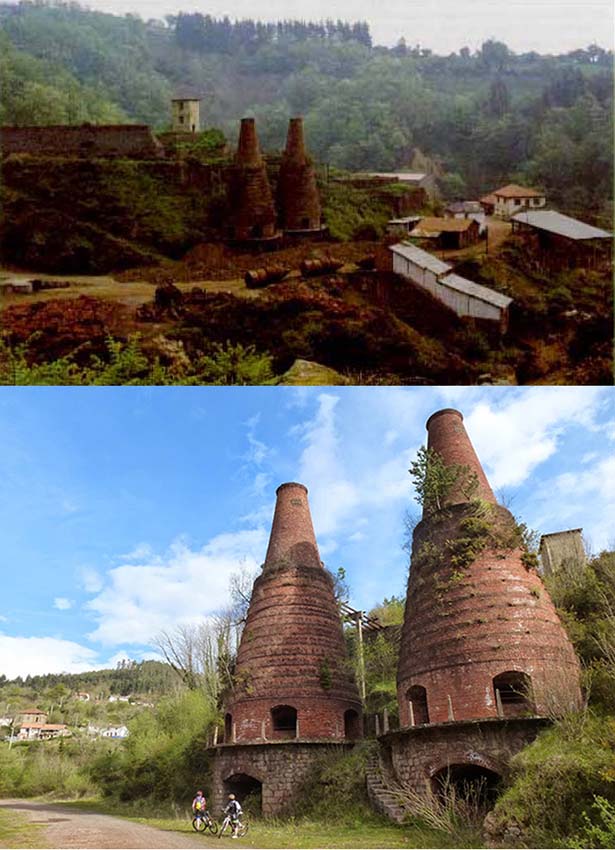

From 1895, the richest ore began to run out, so they started to reuse what had been discarded at first (known by the name of "txirta"). To do so, new devices were used and a final product with a higher level of iron was produced; washeries to take away clay and earth (in 1899, 17 washeries were recorded with 49 trommel washing drums) and calcining kilns to separate the ore from other rocks (in 1919 there were 45 fully operational kilns).

As an example of how much was mined in these mountains, the Orconera Iron Ore Cº Ltd., one of the main companies, exported more than 7 million tons during the last years of the 19th century (approximately 20% of the ore in the Bizkaia mining area). In 1894 alone, more than 1 million tons of ore were extracted, of which over 80% were exported abroad.

In these mines, one of the factors of great importance for the later economic development of Bizkaia was the difference between mine owners (mostly local) and leaseholders who worked them (usually foreign capital companies). Most of the capital accumulated by local land-owning families was destined for reinvestment in industrial infrastructures on the banks of the river.

*Texts: www.ezagutubarakaldo.net

THE GREAT IRON MINE: CONCHA II OR BODOVALLE (Spanish)

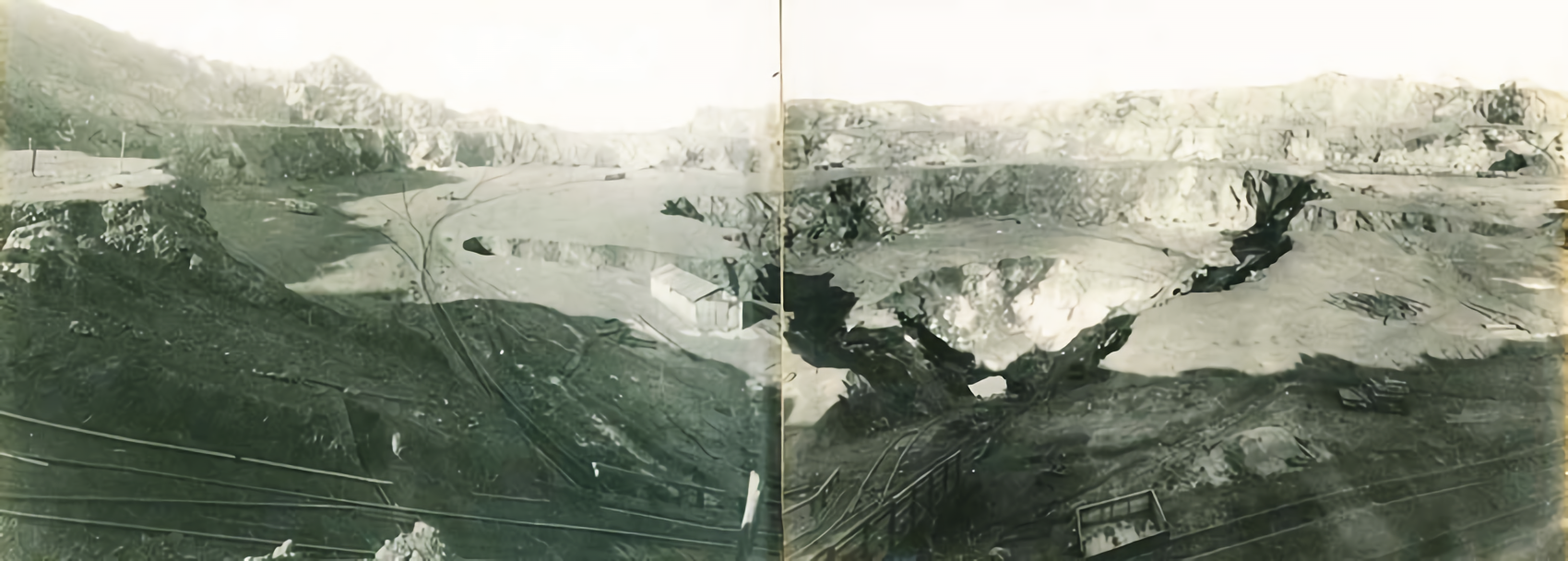

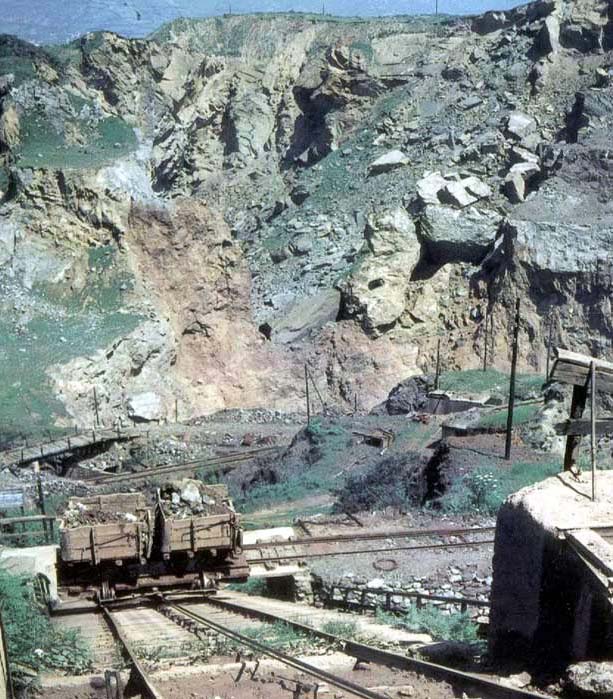

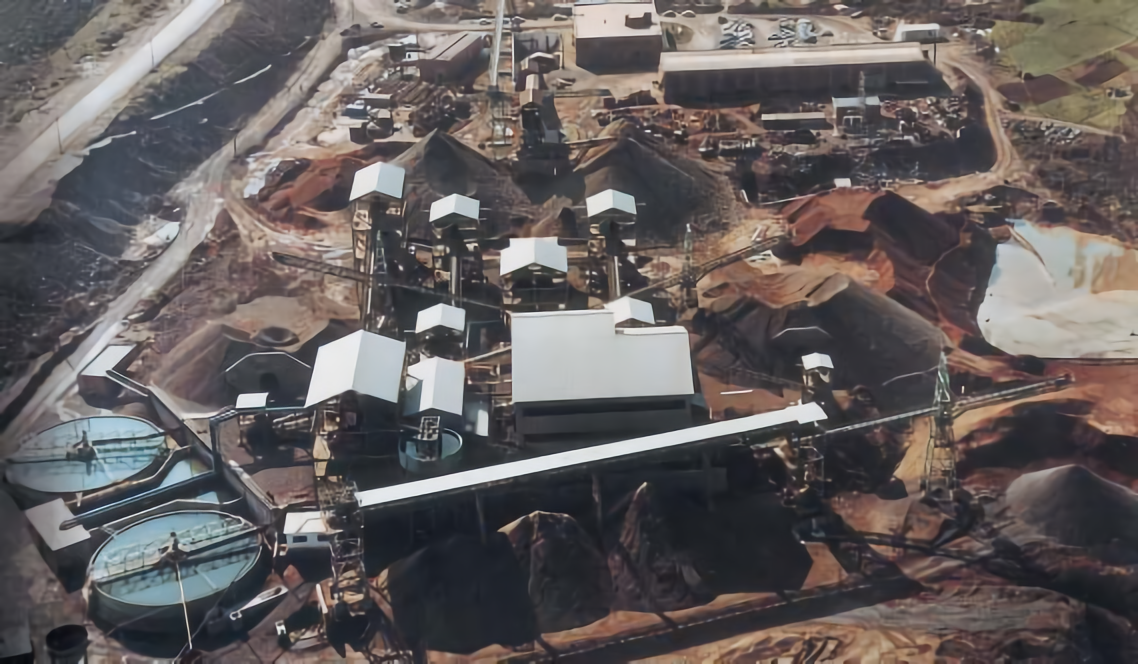

This walk ends at the enormous hole left by the last iron mine in operation: the Concha II mine (when it was operated by the Franco-Belga company) or Bodovalle (under the control of Agruminsa) (4). Its opening in 1960 marked the total displacement of the old town of Gallarta, and the town you can see today is almost entirely the result of this move. It was operated by the Altos Hornos de Vizcaya iron and steel company through its subsidiary Agruminsa until it closed in 1993 because it was not profitable.

With 500 workers, in the 1970s it became the second largest iron mine in Europe. The mine you can see is 700m long, 350m wide and 150m deep. The bottom is 37m below sea level, which explains the current flooding with the water that can be seen at the bottom.

This is the result of having used up the iron ore on the surface, which meant that operating permits were obtained in 1984 for underground galleries stretching over 50 km below the surface. Inside, it contains great chambers as big as a cathedral.

Next to the mine is the building of the old slaughterhouse, now the Mining Museum (Spanish) (5) and its future extension next to with its spectacular balcony overlooking the mine pit. This Museum (Spanish) explains the use of iron in various historical periods but basically it focuses on explaining the items that were recovered when the mines were abandoned.

It is worth looking at the model that explains the change of location of the town of Gallarta and its replacement by the Bodovalle mine, and the model which explains the profusion of individualized miners’ transports of all kinds allocated to each mining company, illustrating to a great extent the radical change in the landscape well beyond mining activities.